Commisioned by Big Bottle Wines Pty Limited in 2003 to design & build a large wine bottle washng & filling line.

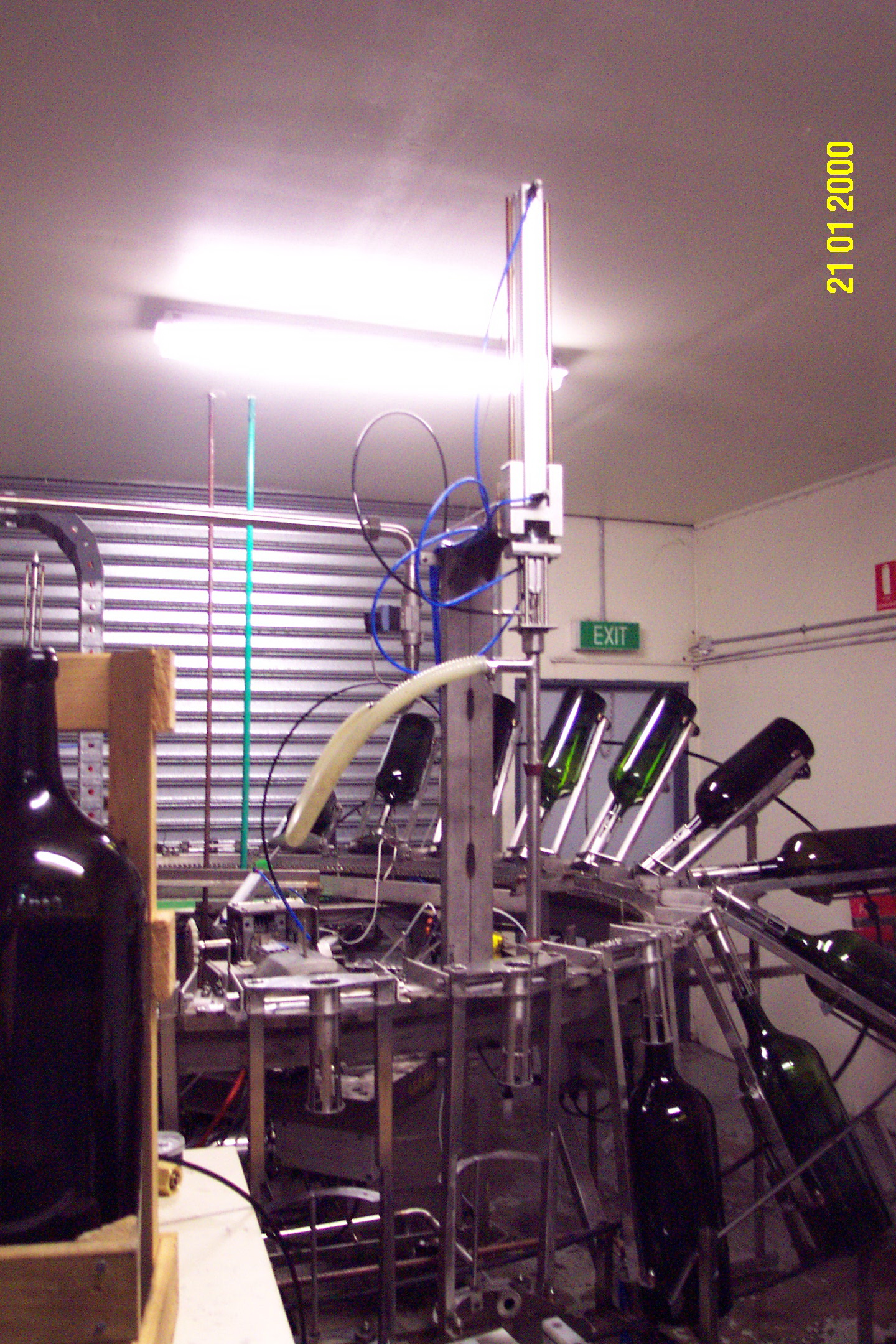

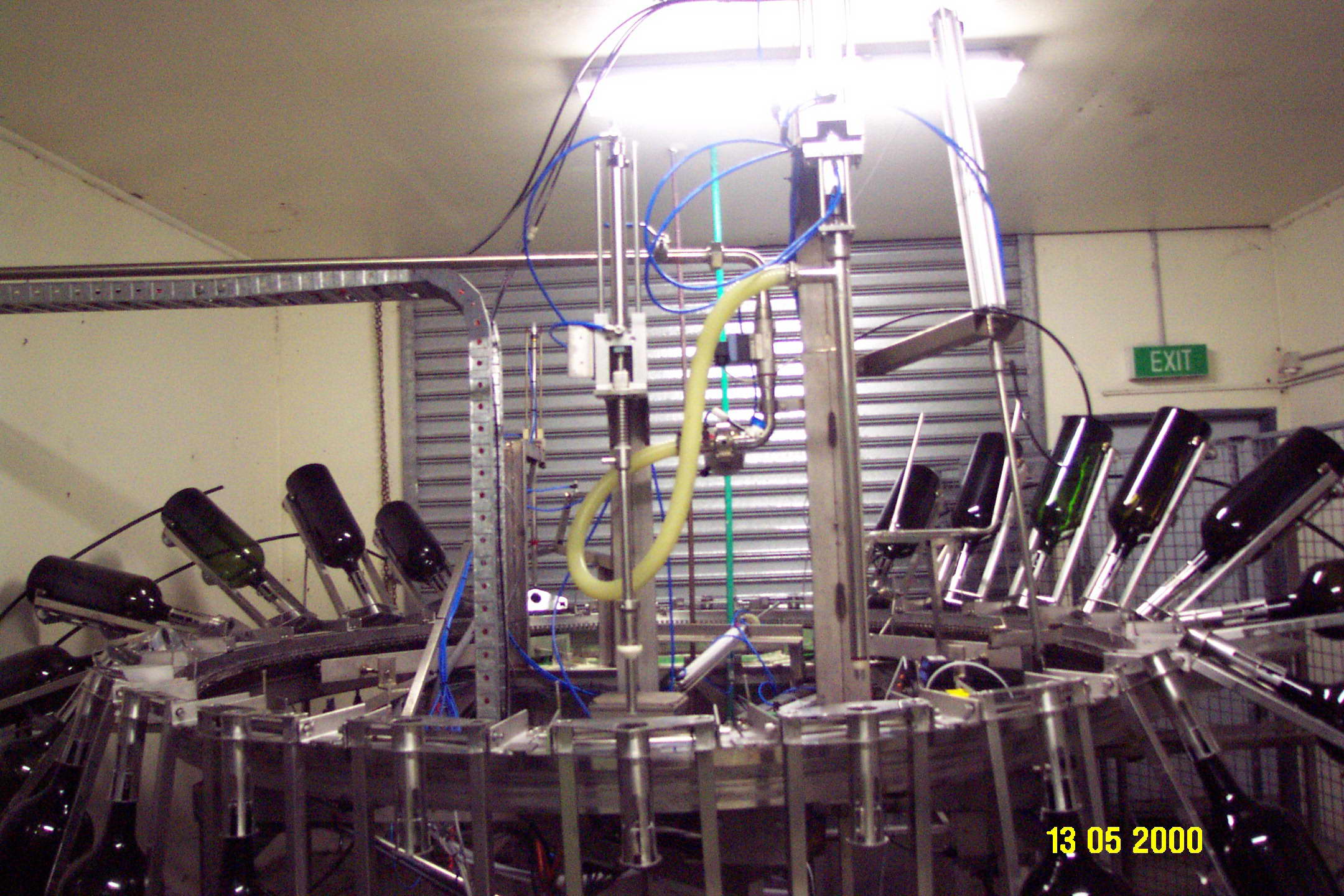

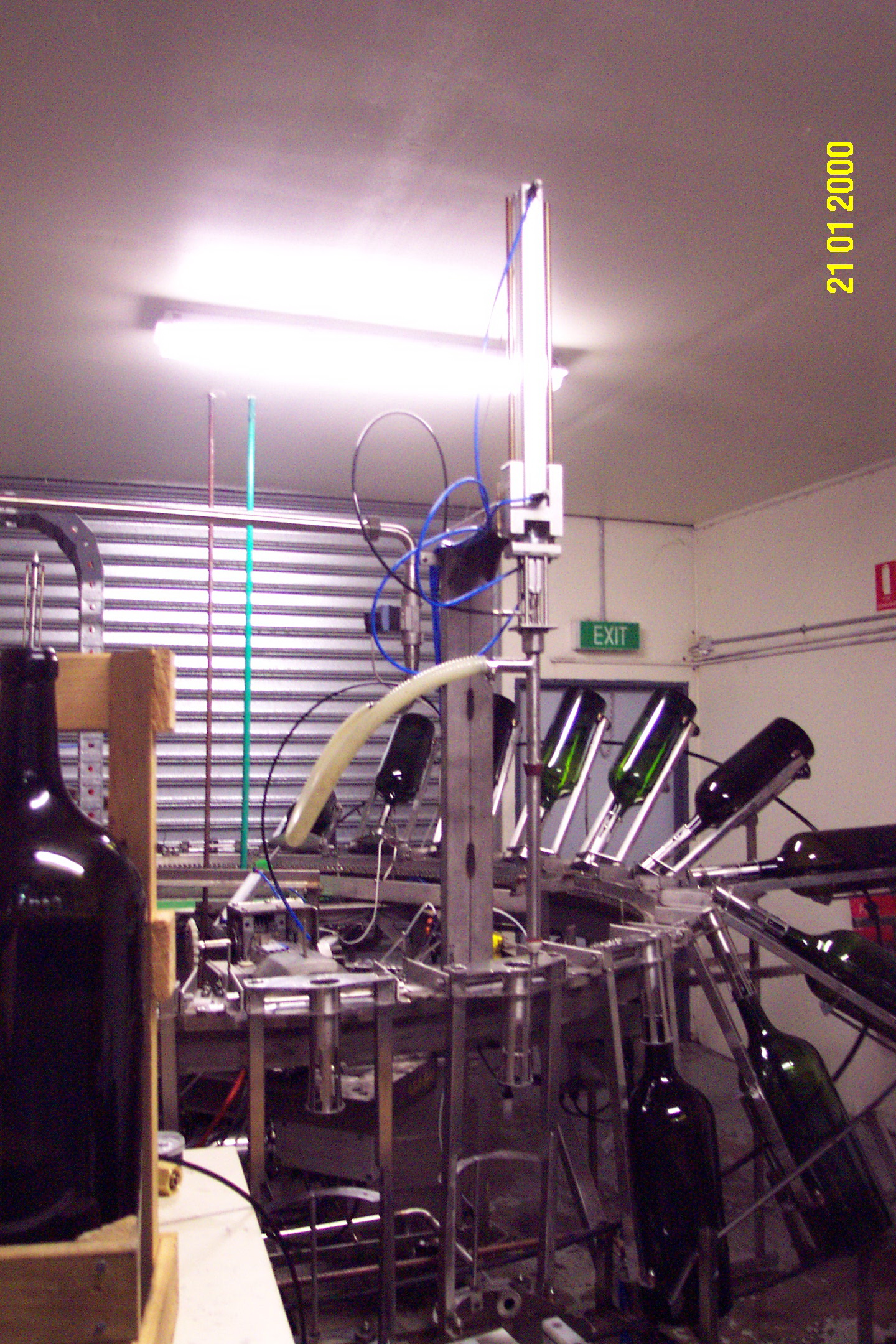

Throwing convention out the window I designed a rotary system that picked up the bottles off an infeed conveyor & transport them in an arc while rinsing the old wine out then immersing them in an ultrasonic washer & heated to 55C using 3kW of ultrasonic transducers to wash the glass bottles inside & out. The bottles then lifted from the tank & drained before being rinsed. The next stage was a nitrogen purge of teh bottle before bing filled. Caping was then performed and the bottles labelled & hand packed for dispatch.

The control system for this unit also controlled a wash staion built as an add on to wash the 1500L wine transportation tanks. Was the first rotary ultrasonid immersion washer in teh wrld to the best of my knowledge. Indeed have not seen anything like it since. The wash effectiveness was far superior to standard chemical spray wash. Concept was Solid modelled first then put into production. Machine took 6 months to build & commision.

OEM Control Panels

CIP Controllers